Why Membrane Switches Are Preferred for Their Thin and Compact Layouts

The Ultimate Resource on Membrane Changes: Layout, Capability, and Applications

Membrane switches act as an intriguing intersection of style and performance, playing a crucial duty in modern interface across numerous industries. This source unloads the necessary parts that add to their effectiveness, consisting of visuals overlays and circuit traces, while additionally clarifying the devices behind their stress activation. As we discover the varied applications of membrane layer switches, it ends up being apparent that their versatility and sturdiness are important in atmospheres ranging from healthcare to consumer electronics. The subtleties of their layout and operational principles might expose even much deeper insights worth considering.

Recognizing Membrane Buttons

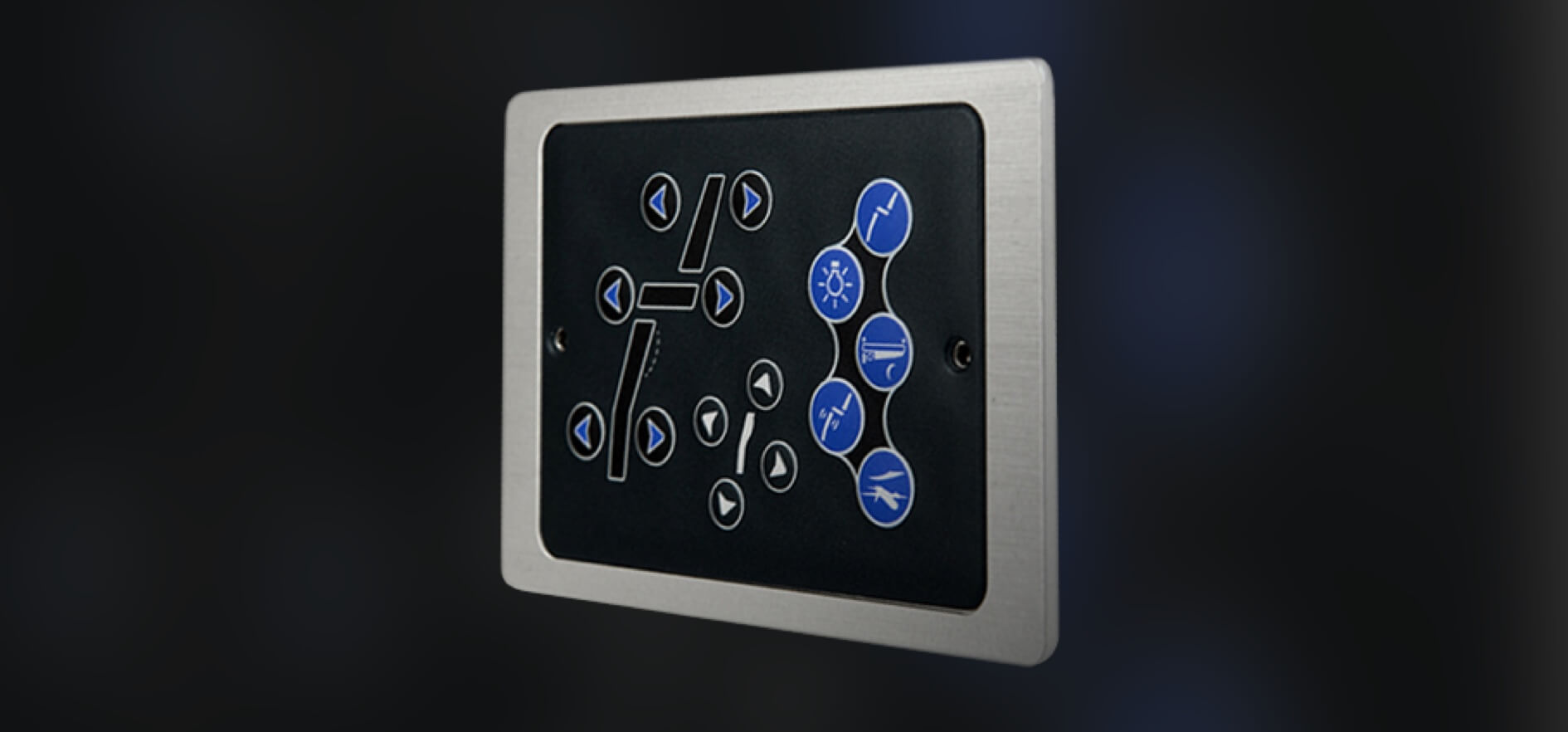

Membrane switches are a kind of user interface modern technology widely utilized in various electronic tools, characterized by their thin, adaptable style and capability. These switches contain numerous layers that include visuals overlays, sticky layers, and wiring, allowing a effective and compact interface for customers. They can be located in devices, medical gadgets, and commercial control board, providing a trusted method for individual communication.

Among the key benefits of membrane switches is their ability to withstand pollutants such as dirt and dampness, making them ideal for settings where resilience is vital. Their inconspicuous layout permits for smooth assimilation right into various applications, while the personalized visuals overlays boost customer experience by providing clear visual feedback. Additionally, membrane switches can accommodate a variety of technologies, such as tactile comments and backlighting, additional improving their functionality.

The manufacturing process for membrane layer switches over normally includes screen lamination, die-cutting, and printing strategies, making sure precision and consistency in manufacturing. Generally, membrane switches over stand for a versatile and reliable solution for contemporary electronic tools, integrating functionality with aesthetic charm in interface style.

Secret Components and Design Aspects

A range of crucial elements and design aspects come together to develop an efficient membrane layer switch. At the core, the visuals overlay serves both useful and aesthetic objectives, providing an easy to use interface while shielding internal elements from environmental aspects. The selection of materials, typically polyester or polycarbonate, affects resilience and responsive feedback.

Underneath the overlay, the glue layer guarantees the button sticks securely to the substrate, which can be steel, plastic, or glass. The spacer layer is essential, as it keeps the necessary space in between the overlay and the circuit layers, enabling reliable actuation. Membrane Switches. Circuit traces, usually made from conductive ink or adhesive, are published on an adaptable substrate, allowing electric signals to be sent when stress is applied

Style factors to consider additionally include the plan of responsive domes or embossing that offer physical comments to the customer, improving the general experience. In addition, the layout and spacing of the switches need to be maximized for convenience of use, guaranteeing that customers can browse the user interface with ease. Overall, these components and design elements work synergistically to create a trustworthy, useful membrane layer button customized to certain applications.

Capability and Procedure System

At the heart of reliable performance for membrane layer changes lies their operational mechanism, which helps with individual interaction with a basic yet effective style. These switches operate on the principle of stress activation, where a customer uses pressure to a designated location of the switch (Membrane Switches). This action presses the layers of the button, finishing an electric circuit that sends a signal to the connected device

The building and construction usually consists of a top graphic layer, a glue spacer layer, and a lower circuit layer, which collectively form a robust user interface. When pressure is applied, the leading layer breaks down against the lower circuit layer, permitting conductive traces to link. This design not just makes it possible for clear tactile responses yet additionally makes sure resilience and dependability, as the switches are typically resistant to dirt and wetness.

Furthermore, the my review here versatility of membrane layer changes enables assimilation with different technologies, consisting of LED indicators and microcontrollers, boosting their functionality. By giving a streamlined user interface that lessens mechanical wear, membrane layer changes remain a preferred choice in applications varying from consumer electronic devices to commercial devices, ensuring ideal efficiency and user satisfaction throughout varied environments.

Kinds of Membrane Switches

Another significant classification is lit up membrane layer buttons, which include backlighting to boost presence in low-light problems. These buttons are usually utilized in control panels and control panels where clear presence is essential.

Additionally, there are customized membrane switches developed to satisfy certain dimensional, graphical, and functional needs. These modifications can include distinct shapes, shades, and formats, enabling smooth integration into different devices.

Applications Across Numerous Industries

Just how do membrane layer switches boost functionality throughout diverse markets? In the clinical field, membrane buttons play an essential duty in devices such as analysis tools and individual surveillance systems, where dependability and convenience of cleaning are critical.

In the auto industry, membrane buttons are commonly used in control panels and control panels, offering instinctive controls that enhance chauffeur safety and security and convenience. The customer electronics industry additionally benefits from their lightweight and personalized features, making it possible for sleek styles for smartphones and home devices.

Moreover, membrane buttons locate applications in industrial automation, where they contribute to reliable machinery procedure and monitoring systems. Their resistance to dust and dampness ensures performance in requiring problems (Membrane Switches). Additionally, the food and beverage industry employs membrane layer buttons for devices control, where health and durability are vital

Verdict

In final thought, membrane switches over represent an important development in user interface modern technology, defined by their unique layout and performance. The flexibility of membrane layer changes facilitates their application throughout diverse sectors, from medical tools to consumer electronic devices.

Membrane switches over serve as an interesting junction of style and functionality, playing an check this essential role in modern-day user interfaces throughout various fields.Membrane buttons are a type of customer interface innovation extensively utilized in various digital devices, defined by their thin, adaptable style and capability.At the heart of efficient capability for membrane switches over lies their functional mechanism, which assists in user interaction via a basic yet efficient design. These buttons operate on the principle of stress activation, where an individual applies pressure to an assigned location of the button.In conclusion, membrane switches over stand for a vital innovation in individual interface modern technology, characterized by their distinct style and capability.